Tapping Machine

Machine Name : Tapping Machine

Machine Model No. : KIP-M12

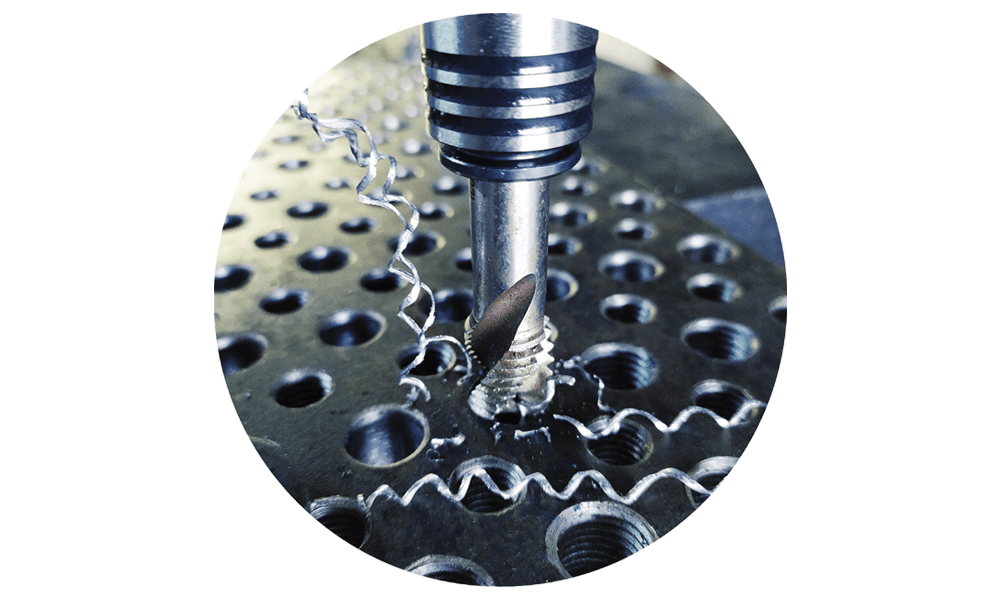

| Tapping Range | M3 to M12 |

| Maximum Spindle Speed | 625 rpm |

| Maximum Working Radius | 1000 mm |

| Maximum Working Height | 550 mm |

| Head Orientation (Way to work) | Universal Head (Vertical & Any Direction) |

| Control Way | Touch |

| Servo Motor Power | 600 W |

| Voltage | 220V, 50Hz, 1-Phase |

| Tapping Collet | Couple Dia. 19 with ISO Standard |

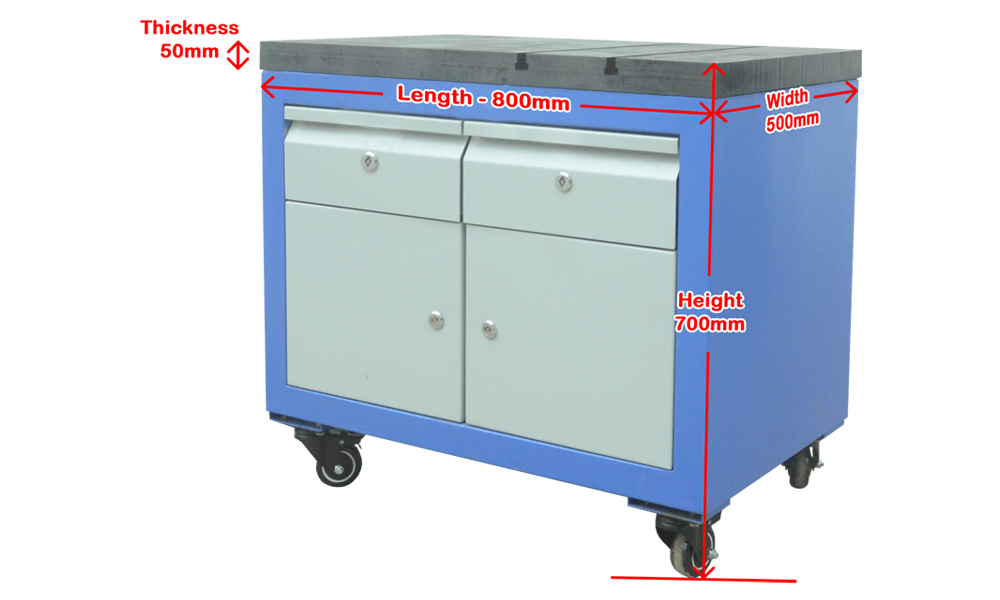

| Packing dimensions L x W x H | 700×610×220 mm |

| Gross/ Net Weight | 24/ 27 kg |

Collet Type: Quick Change Tapping Collet

Couple Diameter of collet: 19mm

| Sr. No. | Tap Size (Metric) | Collect (Tap Shank) Holding Capacity (mm) | |

| Shank Diameter | Square | ||

| 1 | M3 | 3.15 | 2.5 |

| 2 | M4 | 4.0 | 3.15 |

| 3 | M5 | 5.0 | 4.0 |

| 4 | M6 | 6.3 | 5.0 |

| 5 | M8 | 8.0 | 6.3 |

| 6 | M10-DIN | 10.0 | 8.0 |

| 7 | M12 | 9.0 | 7.1 |