UNIVERSAL TOOL & CUTTER GRINDING MACHINES

Machine Name : Universal Tool & Cutter Grinding Machine

Machine Model No. : KIP-600F/Q

| Working table area | 130 x 550 mm |

| Cross travel of the table (X axis) | 260 mm |

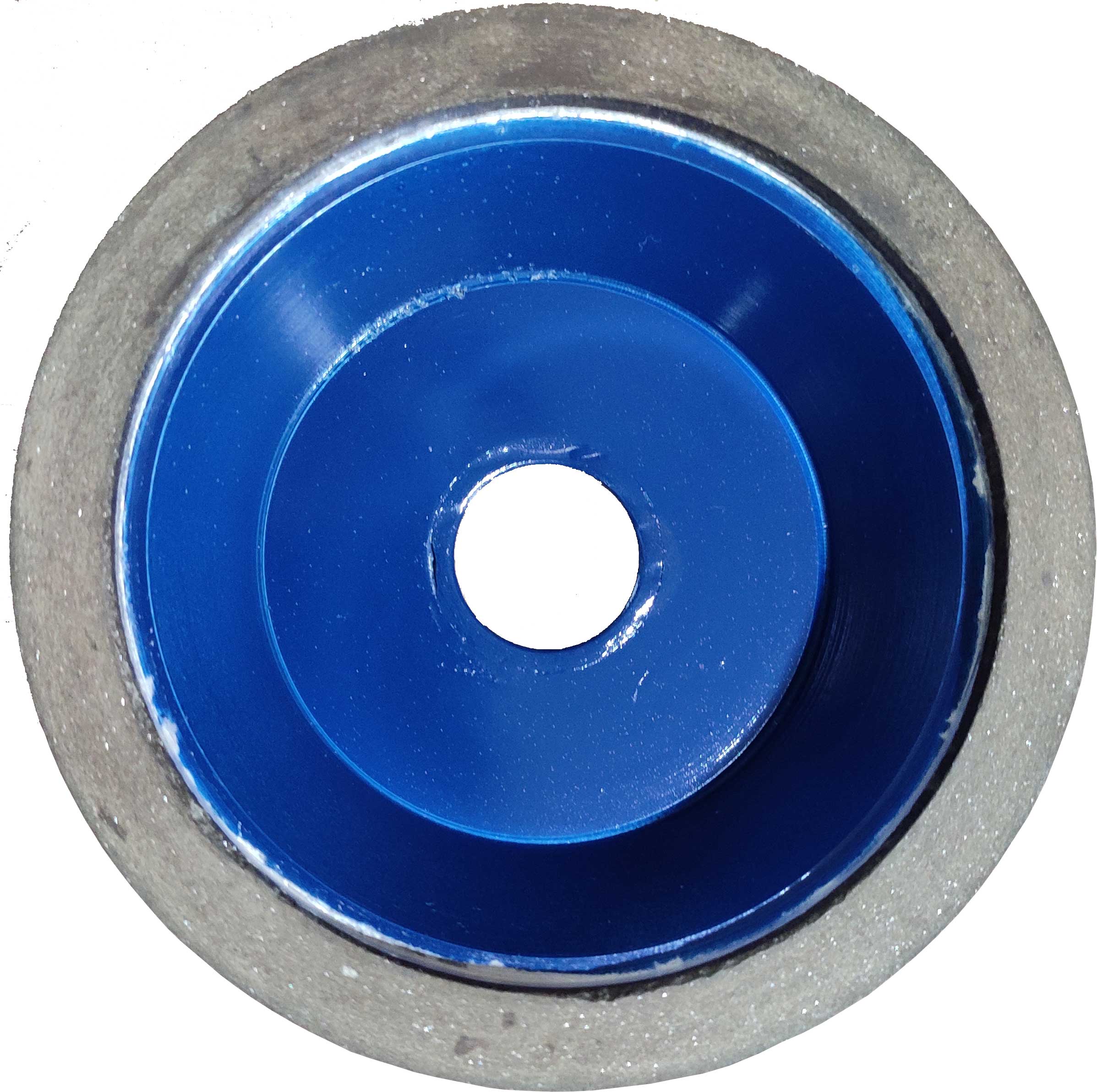

| Grinding wheel | SDC for Carbide (2Pcs = 4 to 6mm & 7 to 13mm) |

| Horizontal travel of the table (Y axis) | 150 mm |

| Vertical adjustment for wheel head | 160 mm |

| Max. Grinding Length | 265 mm |

| Max. Grinding Diameter | 250 mm |

| Rotation angle of wheel head | 360° (Vertical/ Horizontal) |

| Packing dimensions L x W x H | 39 x 36 x 36 cm |

| Grinding wheel size | 150 x 16/50 x 32 mm |

| Speed of grinding wheel | 2800 rpm |

| Main Motor Power | ¾ Hp, 380V (3 Ph) |

| Supplementary Power | 1/2 Hp, 220V (1 Ph) |

| Net/ Gross weight | 160/ 168 kg |

| Machine size | 740x630x700 mm |

| Packing dimensions L x W x H | 630x630x700 cm |